Who We Are

J-Mark is a Tier 1 supplier of accessory components and systems to the automotive industry with products shipped worldwide to dealerships, regional stocking facilities, and production line support facilities for Just-In-Time delivery.

As a privately held company, we are able to quickly react to changes in market trends or customer needs. Our modern 75,000 square foot facility contains the administrative headquarters, an engineering center, production facilities, and safeguarded warehouse storage.

It is our philosophy that our employees are our greatest strength, a belief that is continuously reinforced by feedback from our customers. We take pride in the quality of the products we produce, the ingenuity of the products we design, and support offered to our customers. Please take a moment to review our journey that began almost 60 years ago.

1962

J-Mark began as a custom metal stamping / fabrication company. Soon after J-Mark introduced a proprietary line of service station items (lube spouts, oil filter wrenches, etc.).

1975

J-Mark transitioned into the truck and van accessory market with a proprietary line of aftermarket running boards, splash guards, and tailgate protectors.

1980

Various assist step innovations are marketed via early advertisements. J-Mark is granted the first of many U.S. patents for advancements in the automotive accessory market.

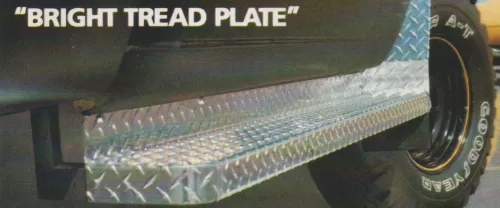

1981

J-Mark's first OEM contract began with American Motors Corporation (AMC), which was later purchased by Chrysler. The project was a diamond-plate aluminum running board for the Jeep brand vehicles.

1983

J-Mark's relationship with Ford Motor Company began when J-Mark was selected as Ford's supplier of running boards for the Ranger truck.

1990

J-Mark partners with Sears to begin selling aftermarket automotive accessories nationwide. The following year, J-Mark is recognized by Sears as an outstanding supplier for products and service; an award presented to only the top 75 of 10,000 total suppliers.

1992

Construction is completed on 38,000 square foot addition to J-Mark facility.

1994

In 1994, J-Mark provided project management for the industry's first paint-to-match OEM plastic truck steps with Chrysler.

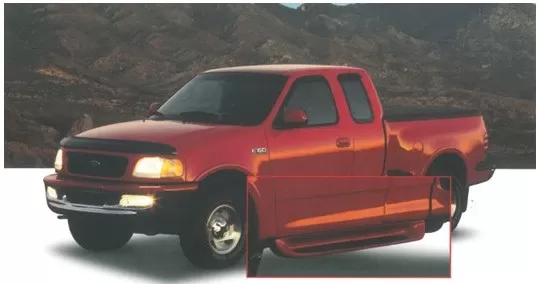

1995

J-Mark receives certification to the new QS9000 quality standard, which was a joint effort developed by Detroit’s “Big Three” (General Motors, Chrysler, and Ford). J-Mark is also selected as Ford’s supplier of running boards for the all new F-150 truck. These steps include 7 body matching colors.

2005

J-Mark receives certification to ISO9001, as QS9000 is phased out.

2009

J-Mark receives certification to ISO/TS 16949, an automotive industry quality standard based on the ISO9001 quality standard.

2011

J-Mark achieves GM’s Gold Supplier Status for 99% On Time Direct Shipping and Overall On Time Shipping (OTS).

2012

J-Mark achieves GM’s Platinum Supplier Status for 100% On Time Direct Shipping and Overall OTS. J-Mark has maintained annual suppliers awards since.

2013

Installation of solar panels is completed at J-Mark, as an effort to contribute to The Green Initiative.

2015

J-Mark adds suite of Siemens software including NX, Teamcenter, and VisMockUp to support OE native 3D design and product lifecycle management (PLM), and becomes an Integrated Design Supplier to General Motors.

Today

We continually strive to improve our internal quality management systems, the quality of our products, and offer customer support that is second to none. As we continue to grow, we would like to invite any potential customers or suppliers to contact us with any inquiries you may have.

2023 - Move to Baldwin

J-Mark Products moves to Baldwin!